Seams are everywhere.

The world has seams. There I said it. As I look around our design studio now, I am surrounded by them. Wherever two different pieces of something come together, there is a seam.

My relationship with seams has evolved significantly over the years. As a much younger man, I felt like seams were something that had to be conquered. I felt the compulsion to eradicate seams from my work so that things appeared more monolithic. I was at war.

Clients would reinforce this adversarial relationship when I delivered products to them. They would point to any vestige of a seam and ask how I was going to cover it. This confirmed to me that finding a way to obliterate seams was the right thing to do.

“When I walk and my foot hits the ground it makes a foot shaped seam. I can choose to acknowledge it or to ignore it. If I am walking in the sand, that imprint and the division between where my foot was and the surrounding sand will remain for a bit and I can look back and admire it. If I am walking on concrete, that seam will disappear as soon as I lift my foot. Whether we choose to ignore, minimize, or celebrate them, they are only seams; they are part of our world.” –Scott Metelko, AST Exhibits

One project in particular stands out. We were building modular risers for a theatrical production. We took great care in designing the risers so that they would be as versatile as possible. They needed to be strong enough to withstand decades of repeated use and versatile enough to be used in configurations that we had yet to dream of.

The risers also had to be transported several times each year and needed to fit through various sized doors and fit into the different trucks that would transport them. There were units of different widths and heights, ones that could be easily rolled around the stage, and even modular pieces designed to connect the larger pieces into massive stage constructions.

I was understandably proud of the engineering solutions as well as the quality of the finish on the pieces. Yet for all that, the client pointed out that where the large pieces came together, there was a seam. I was devastated. They were right and there was nothing I could do about it.

Forget the fact that under theatrical lighting and when viewed from the audience, the seams completely disappear. That is not how the client first experienced the product. Those are not the conditions under which they form their first impressions. Under the harsh work lights and viewed from close enough to touch, the seams really worried my client. I worked hard over the next several weeks to convince them that the seams were the trade that they made for the functionality of the riser system. Now I realize that was the wrong approach.

The fact that something is made from multiple parts should not be cause for concern. Nor should it be an issue that the defining lines between those parts are visible. The concern should be when those lines are not given proper care or when they are not artfully handled.

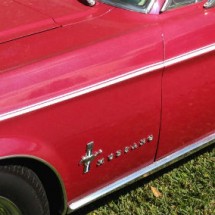

Automotive design is a great example of how to handle seams well. Given proper care, the space between moving parts can enhance lines or soften silhouettes in surprising ways. Frequently seams are even added where they are not strictly necessary because of the effect they have on the lines of the design.

So now I treat seams much less like an enemy and more like a tool. If necessary seams do not enhance a design visually, then I will minimize them. If there is a way to use them to enhance the overall design, then I look for ways to use them for that purpose. One thing that I will not do anymore is pretend that I live in a world without them. I am even finding that our clients respond to this kind of perspective, too.

Take a look around your environment. Consider your relationship with seams. Let us know what you see- reply to this email or meet us over at our Facebook Page to comment.